1,000 Llitres per Hour Skid Mounted Electric Pasteurisers

or

Call +44 (0)1777 717546

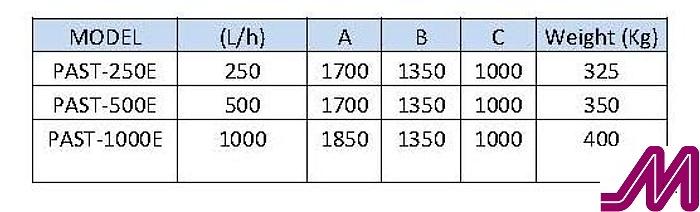

Specifications

| Manufacturer | 1,000 Llitres per Hour Skid Mounted Electric Pasteurisers |

Description

The MIM range of compact electrical pasteurisers has been designed to carry out the thermal treatment of milk and its by-products, soft-drinks and juices. The objective is to eliminate the pathogenic micro-organisms through the application of high temperature during a short period of time.

Pasteuriser unit made up of :-

- Heat exchanger with 0.5mm plates in AISI 316 and gaskets in NBR, frame in AISI 304.

- Centrifugal pump INOXMIM FL31CI for milk feed.

- Food-grade hydraulic circuit DIN11851 with orbital welding.

- Holding tube for maintaining temperature.

- Divert valve for non-pasteurised product, pneumatically actuated.

- By-pass system to regulate the temperature of the pasteurised product and graduate the outlet temperature of the milk.

- Manual butterfly valves with multi-position handles to operate.

- Temperature probes PT100 to control the fluid.

- Hot-water generation system: heating coils, centrifugal pump for recirculation of water INOXMIM FL20C, temperature probe PT100, water inlet valve with automatic regulation and non-return valve, safety valve, expansion vessel, pressure gauge and purge.

- Pneumatic system to regulate and operate with flow-regulating valve, filter, pressure gauge and solenoid.

- Tank of 25 litres for the preparation of cleaning solutions.

- CE marked control panel with:

- 7” touch screen

- Digital thermograph with temperature register

- USB port to extract information

- Operation of solenoids

- Control of pumps

- Emergency stop

- Led indicators

- Switches

- Control box on stainless AISI 304

- Mounted on platform supported by 4 anti-vibration feet

- Made in stainless steel AISI 304

- Standard Voltage 3 phase / 400v / 50Hz

Options

- Different thermal cycles according to client’s requirements.

- Plate heat-exchanger of 4 sections for outlet to homogeniser, skimming machine, etc..

- Holding tube with longer retention times.

- Electrical power matched to energy requirements for specific thermal cycle.

- Materials in contact with the product stainless steel AISI 316.

- Other voltages and frequencies according to country of destination.

- A chiller unit for cold water generation can be incorporated on request.

Common services requirements:

- Compressed air: 1 Nm3/h.

- Hot water for models 250, 500 y 1000 l/h and made with the pump in the hot water generation circuit. The automatic filler valve constantly maintains the circuit full at a pressure of 1.5 bar.

- The flow of cold or glycol water (for cooling to 4°C) for models 250, 500 and 1000 l/h is 700, 1300, 2200 l/h respectively.

- Energy consumption of cold or glycol water (for cooling to 4º C) in models 250, 500 and 1,000 l/h is 3000 Frig/h, 6000 Frig/h and 12000 Frig/h respectively.